| |

|

|

|

|

| |

|

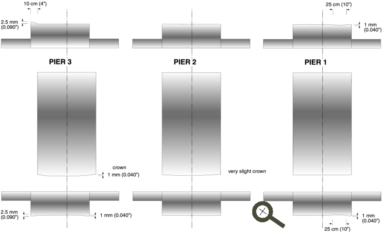

| Measurements of roller and tire profiles with an aid of ultrasonic range sensors for accurate description of profiles. Rendered measurement data is used to make a clear distinction between various types of profiles (convex, concave). Distinction between regular and tapered cylinder is also made. |

|

| |

| |

| |

| |

| Shaft bending (deflection) at rotation is measured with an aid of electronic dial probes and ultrasound range sensors. The results of measurements are put out in a form of deviation from acceptable tolerances and are used as an indication of overloading. Further analysis may point out to an existence of "hidden" crank, e.g. irregular shell radial runout in the vicinity of the tire. |

|

| |

|

| Detailed explanation and examples can be found on Information page. |

|